You want to know how long your HVAC system will last because nobody likes surprise expenses. The short answer is 10 to 25 years. But that range is so wide it’s almost useless without context.

This guide breaks down what actually controls your system’s lifespan and what you can do about it. By the end, you’ll have a clear picture of where your system stands and how to plan ahead.

Key Takeaways

- Your system type and local climate set the baseline for how long it will run.

- Regular professional maintenance is the biggest factor within your control.

- Catching problems early prevents breakdowns during the worst possible weather.

Small Problems Become Big Ones Fast

Maybe you’ve noticed your system making a new sound. Or one room stays warmer than the others. These things are easy to brush off until the system stops working entirely on a 95-degree day.

That’s when most people start asking: how long was this supposed to last? The worry isn’t really about the machine. It’s about the cost and the disruption to daily life. Understanding what affects your system’s lifespan helps you avoid that panic moment.

The Starting Point: Your System Type

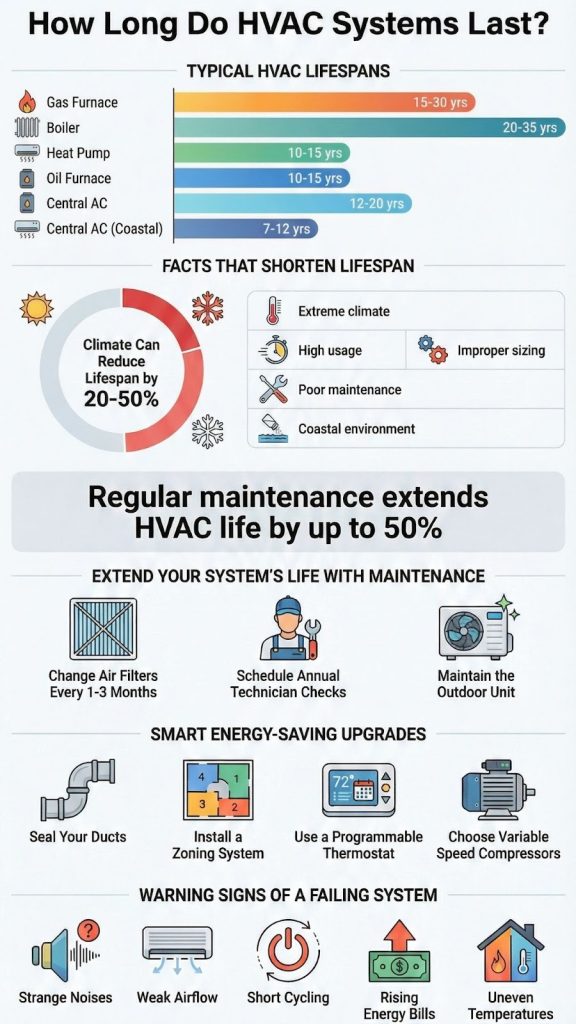

Different HVAC equipment lasts different lengths of time. A gas furnace is built to handle years of heavy use. With reasonable care, expect 15 to 30 years from one. The components are durable and the technology is well-established.

Oil furnaces deal with more internal corrosion from the fuel. They typically run 10 to 15 years. The combustion process creates byproducts that wear down parts faster than gas systems.

Air conditioners have a different job entirely. They battle heat and humidity constantly during summer months. The average central AC lasts 12 to 20 years. But location matters quite a bit. Near the ocean, salt air eats away at metal parts. Coastal AC units often only make it 7 to 12 years before needing replacement.

How System Type and Climate Shape Lifespan

Heat pumps work year-round for both heating and cooling. That constant cycling wears them out faster than systems that only run part of the year. Expect 10 to 15 years from a heat pump with proper maintenance.

Boilers sit at the other end of the spectrum. A cast iron boiler can run 20 to 35 years with proper maintenance. They have fewer moving parts and don’t face the same stresses as forced air systems.

Think of your HVAC system like a vehicle. A car driven gently on paved roads outlasts one hauling heavy loads on rough terrain. Your climate is the road your system travels every single day. Extreme temperatures, high humidity, and coastal conditions all add stress that accumulates over time.

What Shortens Your System’s Life

| Factor | How It Affects the System | Long-Term Impact |

| Extreme climate | Forces longer and harder daily operation | Accelerated component wear |

| High usage hours | Increases mechanical fatigue | Shorter overall lifespan |

| Poor maintenance | Causes dirt buildup and overheating | Major component failure |

| Improper sizing | Leads to short cycling or nonstop runtime | Compressor and motor damage |

| Coastal environment | Corrodes metal components | Early system replacement |

Some systems fail at 10 years. Others keep running past 25. The difference usually isn’t luck. Several factors work together to determine when your equipment will need replacement.

Climate plays a major role. Extreme heat pushes your AC harder and longer each day. Brutal cold strains your furnace the same way. High humidity forces your air conditioner to work overtime pulling moisture from the air while also cooling. Research shows climate extremes can cut HVAC lifespan by 20 to 50 percent (1).

Usage matters too. A system cooling a large home that runs 12 hours a day wears out faster than one in a small weekend cabin that only operates occasionally. The more your system runs, the faster parts wear down.

But the factor you control most is maintenance. This is where you have real power over your system’s future.

Poor Maintenance and Wrong Sizing Cause Early Failures

Skipping maintenance can cut your system’s life in half. That’s not an exaggeration. It’s what technicians see in the field regularly.

Dust builds up on coils over months and years, and restricted airflow through key components like the HVAC plenum forces the compressor and fan motor to work harder to compensate for reduced heat transfer.

The compressor strains to compensate for reduced heat transfer. A clogged filter makes the fan motor work harder to push air through the restriction. Small problems compound until something breaks down completely.

A well-maintained system might run 20 years or more. A neglected one might struggle to reach 10 years before major components fail.

Common maintenance problems include:

- Dirty air filters that block airflow and strain motors

- Grimy coils that reduce heat transfer efficiency

- Motors that burn out from lack of lubrication

- Refrigerant leaks that go undetected and damage compressors

Wrong sizing causes trouble too. An oversized system cycles on and off constantly because it cools or heats the space too quickly. An undersized one runs nonstop trying to reach the thermostat setting. Both scenarios wear out parts faster than a properly sized unit that runs in moderate cycles.

How to Add Years to Your System

You don’t have to sit back and watch your system age. You can take concrete steps to extend its life and delay replacement costs.

Start with annual professional maintenance. A technician catches small issues before they become expensive repairs. They clean components, check refrigerant levels, inspect electrical connections, and make sure everything runs smoothly. This visit pays for itself by preventing breakdowns and extending equipment life.

Your own habits matter just as much. Change your air filter regularly. If you have pets or allergies, swap it every one to two months. Most homes should change filters at least every three months. A clean filter reduces strain on the entire system and improves indoor air quality at the same time.

Keep the area around your outdoor unit clear of debris, leaves, and plants. The unit needs airflow to work properly. Restricted airflow makes the compressor work harder and run hotter.

Upgrades That Reduce Wear and Save Energy

Credits: Affordable Comfort

A few changes can make your system work less while keeping you just as comfortable, especially when efficiency upgrades align with available HVAC system tax credits that offset costs while reducing long-term wear on major components.These investments often pay off through lower energy bills and longer equipment life.

Sealing your ductwork stops conditioned air from leaking into attics or crawlspaces. Studies suggest that typical homes lose 20 to 30 percent of conditioned air through duct leaks. Your system doesn’t have to run as long to reach the temperature you want when that air actually reaches your living spaces.

Zoning systems direct heating or cooling only to rooms you’re actually using (2). Instead of conditioning the entire house, you focus resources where people are. Less runtime means less wear on parts and lower utility bills.

A programmable thermostat prevents your system from working hard when nobody’s home. Setting temperatures back during work hours and overnight reduces total runtime significantly over a year.

Newer systems with variable speed compressors or two-stage furnaces run more gently than older single-stage units. Instead of blasting at full power and shutting off, they adjust output to match the actual need. They save energy and reduce wear at the same time.

Pay Attention to Warning Signs

Your system usually gives signals before it dies completely. Learning what to watch for helps you avoid emergency breakdowns and gives you time to plan.

Strange noises like grinding, screeching, or banging mean something’s wrong inside the equipment. These sounds indicate worn bearings, loose components, or failing motors. Don’t ignore them hoping they’ll go away.

Weak airflow from vents often points to clogged filters, blocked ductwork, or issues affecting CFM in HVAC systems, all of which reduce proper air delivery and increase strain on blower motors. Check the filter first since that’s the easiest fix. If airflow remains weak with a clean filter, call a technician.

- Rising energy bills with no change in usage often mean your system is losing efficiency and working harder than it should.

- Uneven temperatures between rooms usually point to duct issues or an aging system that can’t keep up anymore.

- Frequent repairs on systems over 15 years old are a sign it may be smarter to replace the unit rather than keep fixing it.

Short cycling happens when the system turns on and off every few minutes instead of running in normal cycles. This points to thermostat problems, low refrigerant, an oversized unit, or overheating components. Short cycling wastes energy and causes rapid wear on the compressor.

FAQs

How long does an HVAC system usually last?

Most systems run between 10 and 25 years. The exact number depends on equipment type, how often it runs, and how well you maintain it. Furnaces generally outlast air conditioners. Systems in mild climates last longer than those in extreme weather. Regular maintenance pushes your system toward the higher end of that range.

Does climate affect HVAC lifespan?

Climate has a big impact on how long equipment lasts. Very hot, cold, or humid weather makes your system work harder every day. Parts wear out faster under constant strain. Coastal areas cause extra damage because salt air corrodes metal components. Systems in temperate climates face less stress and often last longer with the same level of care.

Which HVAC system lasts the longest?

Boilers and gas furnaces typically last longest among common residential systems. Boilers can run 20 to 35 years with proper care. Gas furnaces often reach 15 to 30 years. Heat pumps and air conditioners work harder throughout the year, so they usually last 10 to 20 years. Maintenance and installation quality still affect the final number significantly.

How does maintenance help my HVAC system last longer?

Maintenance keeps components clean and running properly. A technician spots small problems before they become major repairs. Cleaning coils, checking motors, and verifying refrigerant levels reduce strain on the system. With regular professional and homeowner care, an HVAC system can last 30 to 50 percent longer than one that’s ignored.

How often should I change my air filter?

Most homes should change filters every three months at minimum. Homes with pets, allergies, or dusty conditions need changes every one to two months. A clean filter allows air to flow freely through the system. This reduces stress on motors and helps the equipment run more efficiently. It’s one of the cheapest ways to protect your equipment.

Can poor installation shorten HVAC life?

Poor installation definitely shortens lifespan. An oversized system cycles too frequently, causing wear on the compressor. An undersized one runs constantly trying to meet demand. Both scenarios cause extra wear compared to properly sized equipment.

Correct sizing and proper ductwork help the system operate as designed. Quality installation leads to longer life and lower energy costs.

What are warning signs my HVAC is failing?

Watch for unusual noises, weak airflow, uneven temperatures between rooms, and frequent cycling. Rising energy bills without changes in usage signal declining efficiency. Frequent repairs, especially after 15 years of operation, suggest the system is nearing the end of its useful life. Catching these signs early gives you time to plan replacement on your schedule.

Does using my HVAC more shorten its life?

Heavy use does cause faster wear on components. Systems running all day in large homes or extreme climates age quicker than those with lighter duty cycles. Zoning systems, smart thermostats, and good insulation reduce how long your system needs to run each day. Less strain means longer-lasting parts and delayed replacement.

Is it better to repair or replace an old HVAC?

Age and repair cost guide this decision. If your system is over 15 years old and repairs are frequent or expensive, replacement often makes more financial sense. Newer systems run more efficiently and reliably. Putting significant money into major repairs for very old equipment rarely pays off in the long run.

How can I plan for HVAC replacement?

Know your system’s age and current condition. Once it reaches 10 to 15 years, start setting money aside for eventual replacement. Schedule yearly inspections to track how it’s holding up over time. Ask a professional for their honest assessment. Planning ahead turns replacement into a smooth process instead of a stressful emergency.

Planning Ahead Makes the Difference

How long your HVAC lasts depends on several factors working together: system type, climate, maintenance habits, and installation quality. The goal isn’t to run your equipment until it collapses completely. It’s to understand where you stand so you can make smart decisions about repairs, maintenance, and eventual replacement.

A proactive approach turns a potential emergency into a planned upgrade. Your comfort and your budget both benefit from thinking ahead rather than reacting to breakdowns.

Ready to find out where your system stands? The team at Centerline Mechanical can assess your equipment and help you build a maintenance plan that extends its life.

References

- https://pmc.ncbi.nlm.nih.gov/articles/PMC5854721/

- https://www.sciencedirect.com/science/article/pii/S019689042200750